Positive Displacement Pumps

Our nine locations are stocked with a variety of Positive Displacement pumps, as well as seals, O-rings, repair kits, and replacement parts. We take pride in our ability to provide pumps quickly, and at competitive rates. Browse the offerings below, and reach out to us if you don’t see what you’re looking for – we can probably still help!

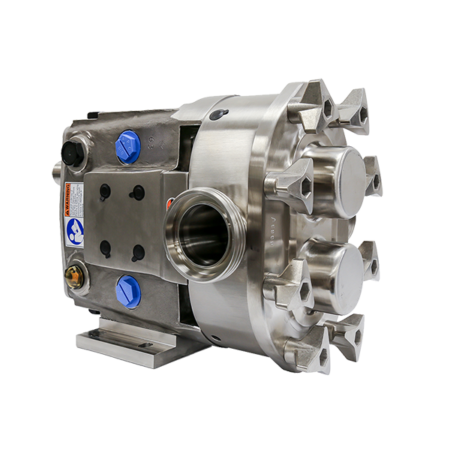

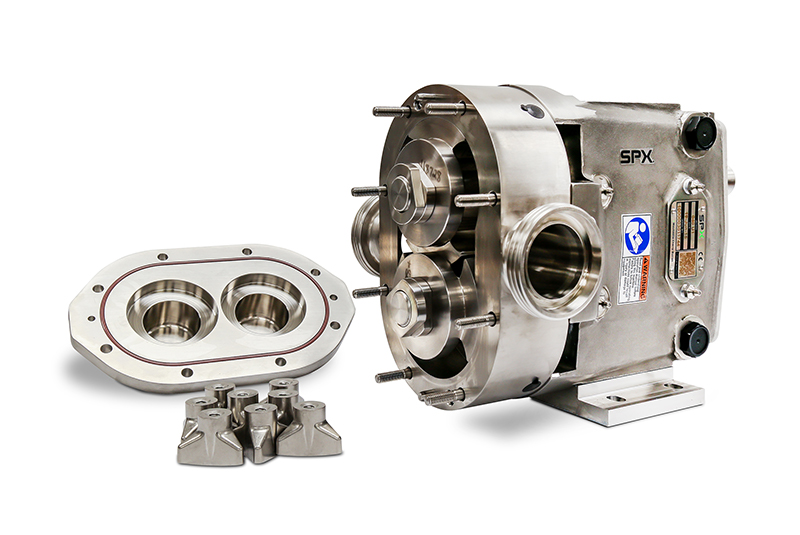

- SPX Universal 1 SeriesVersatile in application, its reliability has made it the industry standard worldwide.

- SPX Universal 1 AsepticSame reliability as the standard U1 with added benefit of having steam or sterile solution circulated to ports, cover, product seal areas.

- SPX Universal 2 SeriesAdvanced sanitation technologies, CIP capable, long life features, and installation flexibility

- SPX Universal 3 SeriesEngineered to perform well in food & beverage, dairy, pharmaceutical, personal care, chemical, and industrial industries.

- APV R-SeriesRugged, long lasting design and efficient performance; great solution for strip-cleaning applications like meat processing