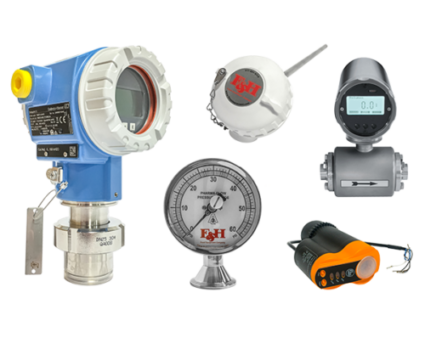

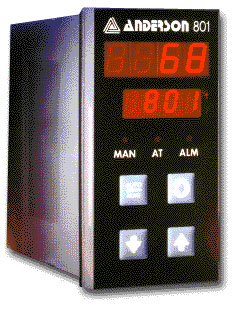

Instrumentation

Process instrumentation is used in countless applications throughout many different processing facilities. F&H has several long-time partners in the area of process controls and instrumentation, meaning we can supply a wide range of quality products from industry-leading brands. No matter what your application requires, we can help you find the right solution.