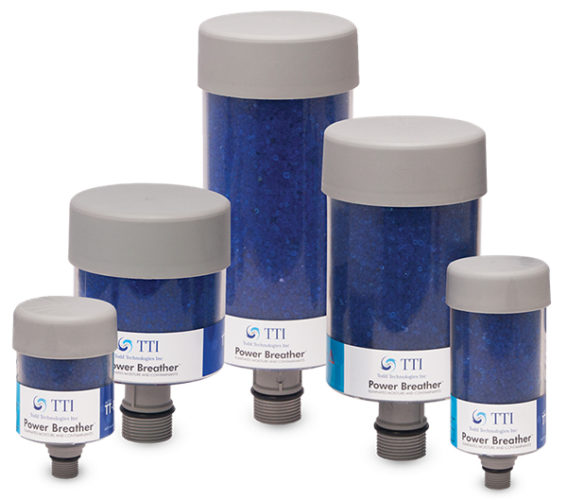

Desiccant Breathers

Desiccant breathers are important because they help to remove small particles and moisture to prevent corrosion and premature wear on reciprocating equipment. The process works like this: air is drawn into your equipment through the breather, and the layered desiccant filter elements remove particles while the desiccant beads take away harmful moisture. During service or shut-down, the desiccant beads attract moisture from inside the equipment reservoir, drying the equipment and preventing harmful wear and tear.